Coil Springs 101: A Beginner's Guide to Suspension Components

Uncover the essentials of car coil springs in this beginner's guide, shedding light on their crucial role in your car's suspension system.

When you think about a car's performance and ride comfort, you might picture sleek designs, powerful engines, or advanced technology. However, there's a critical but often overlooked component that plays a fundamental role in your car's ability to provide a smooth, controlled, and safe ride – the coil spring.

A car's suspension system is like a puzzle, with each piece carefully designed to work harmoniously. It's responsible for maintaining contact between the tires and the road surface, absorbing shocks from uneven terrain, and ensuring stability during cornering and braking. Among the various suspension components, the coil spring is a hidden hero that significantly influences the overall performance.

The Coil Spring: Unseen, Yet Essential

Coil springs are suspension components that, while often hidden from plain view, are essential for maintaining your car's equilibrium. They are slender, coiled pieces of steel or other materials, strategically placed in a car's suspension system. While they might appear simple, their function is anything but.

- Load Support: They support the weight of the vehicle, including passengers and cargo, ensuring a comfortable and controlled ride.

- Shock Absorption: When your car encounters bumps, potholes, or rough terrain, coil springs absorb and dampen the shocks, preventing excessive jolts and vibrations from reaching the cabin.

- Stability: Coil springs help maintain proper tire contact with the road, ensuring stability during turns and emergency maneuvers.

- Ride Comfort: They contribute significantly to the smoothness of your ride, making it comfortable even on less-than-ideal road surfaces.

Types of car coil springs: the application-based classification

Car coil springs can be categorized based on their specific applications within a vehicle's suspension system.

1. Front Suspension Springs

Front suspension coil springs are located in the front of the vehicle and are a crucial component of the front suspension system. They provide support for the front axle or control arms and play a significant role in controlling the weight distribution of the vehicle. Front coil springs work in conjunction with other suspension components, such as shock absorbers or struts, to absorb shocks and maintain tire contact with the road. These springs are essential for steering stability and overall ride comfort.

2. Rear Suspension Springs

Rear suspension coil springs, as the name suggests, are positioned in the rear suspension system of a vehicle. Like front coil springs, they provide support for the rear axle or control arms. Rear coil springs contribute to the vehicle's overall stability, especially during acceleration and braking. They help maintain a balanced ride and work alongside other suspension components to ensure a comfortable and controlled rear-end ride.

3. Performance Springs

Performance coil springs are designed for high-performance and sports cars. These springs are engineered to provide enhanced handling characteristics, such as reduced body roll during cornering and improved responsiveness during rapid maneuvers. Performance springs typically have a stiffer spring rate compared to stock springs, which results in a firmer ride. This firmer ride is favored by enthusiasts who prioritize sporty driving dynamics.

4. Heavy-Duty Springs

Heavy-duty coil springs are employed in trucks, SUVs, and other vehicles designed for heavy loads or towing. They are engineered to handle the increased weight and stress that come with carrying heavy cargo or towing trailers. These springs provide additional support, ensuring that the vehicle's suspension system can maintain stability and ride comfort under heavy loads.

Different vehicles may use various combinations of front and rear coil springs, and the choice of springs can significantly impact the vehicle's overall handling, ride quality, and load-carrying capacity. Therefore, selecting the appropriate coil springs for a given application is a critical aspect of suspension design and maintenance.

What goes into a quality coil spring?

A quality coil spring is crucial for ensuring a safe, comfortable, and reliable driving experience. Several factors contribute to the quality and performance of a car coil spring.

Material Selection

High-quality coil springs are typically made from durable and resilient materials, most commonly high-stress or alloy steel. The choice of material is crucial as it determines the spring's strength, flexibility, and longevity.

Coating and Protection

High-quality coil springs are often coated with protective finishes to resist corrosion and rust. Common coatings include powder coating, epoxy coating, or phosphate coating. These coatings not only enhance the spring's longevity but also contribute to its appearance.

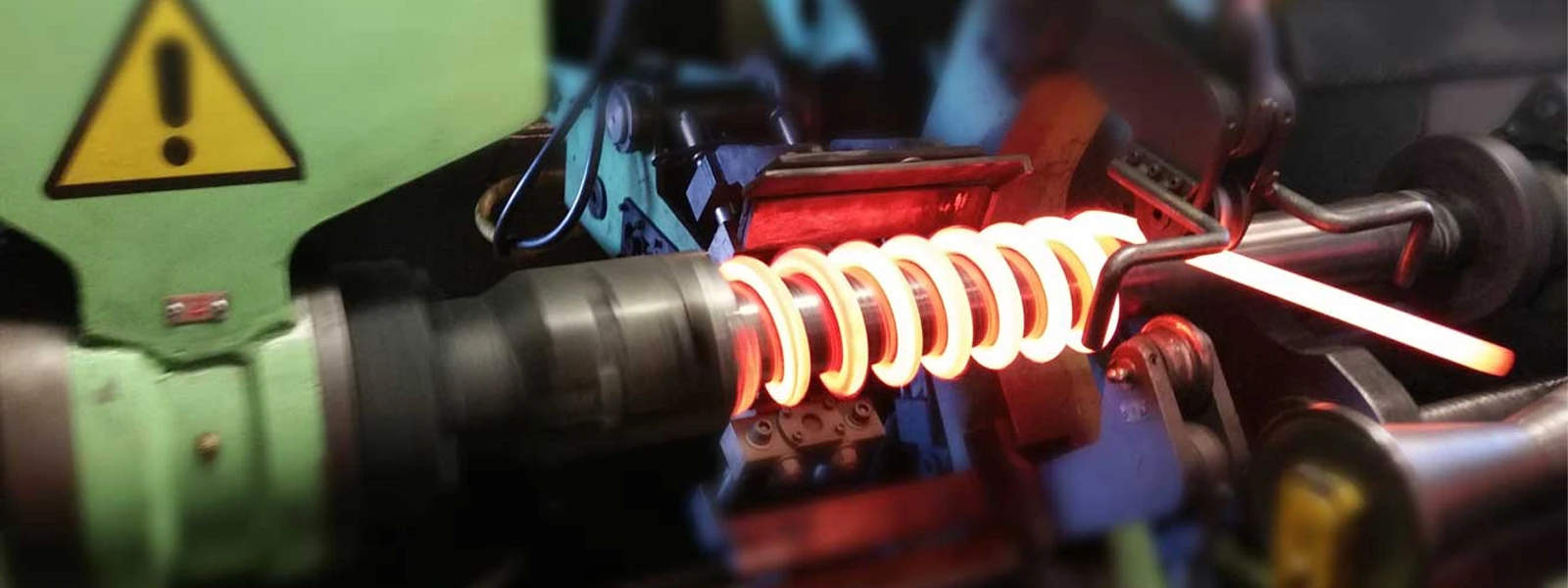

Heat Treatment

Heat treatment processes, such as tempering, are used to improve the mechanical properties of the spring. Proper heat treatment ensures that the spring maintains its strength and flexibility, preventing premature fatigue or failure.

Precision Manufacturing

Precision is critical in coil spring production. Accurate coiling, heat treatment, and shaping processes ensure that the spring meets the specified dimensions and spring rate. Advanced CNC (Computer Numerical Control) machinery and quality control measures are employed to maintain consistency and accuracy in production.

Durability Testing

Quality coil springs undergo rigorous durability and performance testing to ensure they can withstand the demands of real-world driving conditions. Testing may involve simulations of compression and expansion cycles, as well as load-bearing tests to assess the spring's ability to support the vehicle's weight.

Selecting the right coil spring for your car

Before selecting a new coil spring for your car, please make sure that the old one is worn and in need of replacement. check out our other how-to blogs for guidance.

Here are some thoughts on the importance of selecting the right coil spring:

- Vehicle Compatibility: Ensure that the coil spring is specifically designed for your car's make, model, and year. Compatibility is the foundation for a successful choice.

- Spring Rate Matching: Match the spring rate (stiffness) of the coil spring to your vehicle's weight and intended use. An appropriate spring rate is critical for proper ride height, handling, and comfort.

- Quality and Reputation: Choose coil springs from reputable manufacturers known for quality and durability. Read reviews and seek recommendations to ensure reliability.

- Consultation: If uncertain, consult with a professional mechanic or suspension specialist. Their expertise can help you make an informed decision and avoid costly mistakes.

- Alignment and Installation: Ensure proper installation and alignment of the coil springs to maintain safety and performance. Correct installation is vital for the overall suspension function.

A-Premium offers a wide range of high-quality coil springs to meet the diverse needs of customers. Shop for quality coil springs as well as other suspension components at a-premium.com!