How much does it cost to replace a fuel pump in a car?

The fuel pump is the central part of the car. It is the part that sends the fuel to a car's engine and drives the engine. It is used in internal combustion engines. The proper mixing of air and fuel is necessary for the excellent efficiency of the engine.

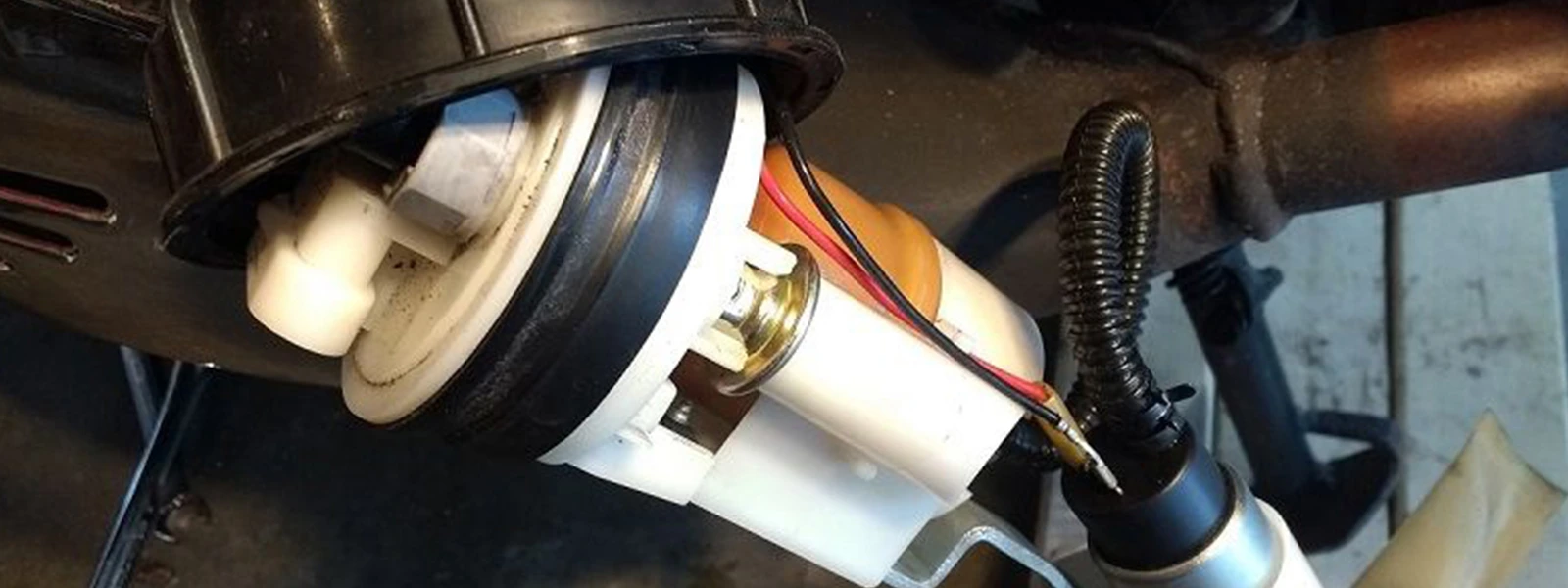

What is a Fuel Pump

The fuel pump is the central part of the car. It is the part that sends the fuel to a car's engine and drives the engine. It is used in internal combustion engines. The proper mixing of air and fuel is necessary for the excellent efficiency of the engine. Petrol in the tank mixes with the air, and an air-fuel mixture is formed in the carburetor. The fuel pump draws the petrol from the tank using a pipe and sends it to the carburetor. The fuel pump can work mechanically, or it can be electrically charged as well.

Both fuel and air are filtered before their combustion. A petrol filter can be used to filtrate petrol in the pipeline. A fuel pump may also consist of a plastic gauze filter or a bowl to catch the impurities. Over the carburetor's air intake, an air cleaner has a paper filter element to clean the air.

If you want to know detailed info about a bad fuel pump, please refer to Can I drive a bad fuel pump

What are the different Types of fuel pumps

Mechanical pumps are low-pressure fuel pumps. Mechanical fuel pumps can be further divided into two categories. One is called a diaphragm-type fuel pump, and the other is a plunger-type fuel pump. Usually, a crankshaft drives this pump. Once the shaft starts to move, a disk comes under its lever, forcing it to move up. The other side of the lever starts going down and ends up pulling the diaphragm with it. The downward motion of the diaphragm creates suction, and fuel draws out from the fuel tank. The carburetor takes the petrol as per the need of the engine with the help of a needle valve.

The plunger-type fuel pump uses the reciprocating action just like the positive displacement pump to suck the fuel from the tank and send it to the carburetor. This pump contains a cylinder whose one side is connected to the crankshaft. As the cylinder moves backward, suction is created, fuel is sucked away, and the forward motion throws the fuel into the carburetor. These pumps are not used nowadays as they require adequate maintenance, and automobiles are now shifted from carburetors to fuel injection systems.

The electrical pump uses a solenoid that is an electromagnet switch. This electromagnet switch is used to pull the diaphragm, and hence the suction is caused. The diaphragm is pulled down as the solenoid starts attracting the iron rod. This breaks the supply of electromagnet, and the diaphragm returns to its position.

Fuel pumps with high pressure are also used to inject fuel directly into the combustion chamber rather than the carburetor. These pumps require almost a pressure of more than 200 pascals. These pumps have flow rails, distribution units, and metering units for delivering the fuel directly into the combustion chamber.

How to know if your fuel pump is faulty

There can be many problems associated with the fuel pump. A good fuel pump has high efficiency, while a bad fuel pump has low efficiency and difficult operating conditions. So, while buying a fuel pump for a car, the customer must ensure some of the properties of the fuel pump. The car will not start if the fuel pump is of bad quality as it will not deliver fuel to the chamber or boiler where combustion will occur, ultimately resulting in lower efficiency.

For more, you may want to check out Can I drive a bad fuel pump, Which type of pump is used in diesel engine, and What is a fuel pump control module

The features of the bad fuel pump are given as follows:

· Lower fuel efficiency:

The lower fuel efficiency indicates that the pump will suck more fuel from the tank for combustion purposes. Ultimately, more usage of fuel will cost the customer more. Pump failure or damage can be avoided by checking the miles and between fill and detecting the decline.

· Rising engine temperature:

Fuel pump motor failure causes the rising of temperature and stalling of the engine. If you notice continuous stalling and a rise in the temperature of the engine, it means that its motor is not working. Stalling can cause multiple effects on the vehicle.

· Noise from the fuel tank:

The failure of the pump bearings can cause a high sound in the vehicle. If a loud sound is coming out from the gasoline tank, then it is very much possible that the fuel pump is broken. If the fuel is polluted or less quantity of the fuel in the fuel tank may also cause a loud sound from the gasoline tank. In the case of proper working of the fuel pump, there will be very little sound from the gasoline tank.

· Difficulty in starting of engine:

If, because of any issue, the pump stops delivering the required amount of fuel in the combustion chamber of the engine, then the vehicle will take time to start. A bad fuel pump does not deliver the required pressure and the engine runs out of gasoline. A polluted fuel or discharging of the battery might be the reason behind the difficulty in starting the engine.

· Problems with pressure gauges:

The engine requires a specific and continual flow of gasoline from the fuel tank. Pressure gauges are used to identify the quantity of fuel delivered to the engine. There can become a problem if there is an issue with the gauges as it will not send the required amount of fuel. In another case, it can happen too that the valve used for the flow of the gasoline from the tank to the engine, does not open and close properly due to which the vehicle can use a greater amount of fuel. The engine does not store or consume additional gasoline coming from the fuel tank.

So, a good fuel pump does not have the above-mentioned properties. It operates at high efficiency and low maintenance conditions. For keeping a fuel pump healthy, the driver must ensure that the fuel tank is filled with fuel all the time. If the driver has left the fuel tank low, then there is a possibility of overheating the fuel pump.

Fixing the fuel pump temporarily

If you start noticing problems related to your pump, you may either exchange it with a new one or can temporarily fix it as well. Bet you want to know more about driving with a bad fuel pump, go for Can I drive a bad fuel pump

For a temporary setup, there are some steps to be followed. The steps are given as follows:

- In the fuel pressure regulator, there is a vacuum line. If by removing the line can, the fuel can be seen inside the line, that means the regulator has failed.

- After checking the regulator, the vacuum line is connected.

- In the third step, the protective cap is removed. This enables attaching the hose of the fuel pressure gauge.

- In the fourth step, the test gauge for fuel pressure is opened.

- Fitting of gauge with the adapter and fixing the line to the test port will complete the fifth step.

- The sixth step is about turning the ignition key to ON mode. In a direct port injector system, the gauge will rise up to 58 PSI. Whereas the throttle body injector’s pressure rises up to 17 PSI. if there is no reflection on the gauge till now, then the examination of the fuse is necessary.

- In the seventh step, the starting of the engine takes place, which drops the pressure up to 52 PSI. This is the indicator that the pressure regulator is working well. But if there is no pressure while the vacuum line operates smoothly, it means that there is a problem with the pressure regulator.

- When the engine is in idle mode or loaded, and fuel pressure gets lower, it means that either there is a fuel pump failure or the fuel filter is blocked.

Cost for replacing a fuel pump

The fuel pump replacement is necessary for the better performance of the vehicle. The actual cost of replacing a fuel pump depends upon certain factors. The cost of a fuel pump is different for different vehicles—the parts of the fuel pump of a car range between 75 dollars and 250 dollars.

The replacement of a fuel pump by a professional cost more than replacing it myself. Replacing a fuel pump is an intermediate-level task. The professional can cost between 400 to 600 dollars. Because of the complexity and difficulty of a stranger, it is better to hire a professional for this job. The professional will have the expertise and proper equipment for this job. The labor cost for the replacement of a fuel pump is usually between 150 to 300 dollars. Labor is usually a smaller part of the cost for this purpose as most mostly 50% and sometimes 80% of the cost is of the parts of the fuel pump. Different companies provide professionals along with the parts of fuel pumps for this purpose. The customer can book a professional online and can buy the fuel pump equipment by itself. Moreover, the fuel pump parts and a professional can be ordered by different companies at a time.