What Does a Control Arm Do?

Vehicles are nothing without an efficient suspension system. The suspension system is responsible for moving the tires in a coordinated and smooth fashion. However, a perfectly synced wheel motion significantly depends on a control arm. But what is a con

Vehicles are nothing without an efficient suspension system. The suspension system is responsible for moving the tires in a coordinated and smooth fashion. However, a perfectly synced wheel motion significantly depends on a control arm.

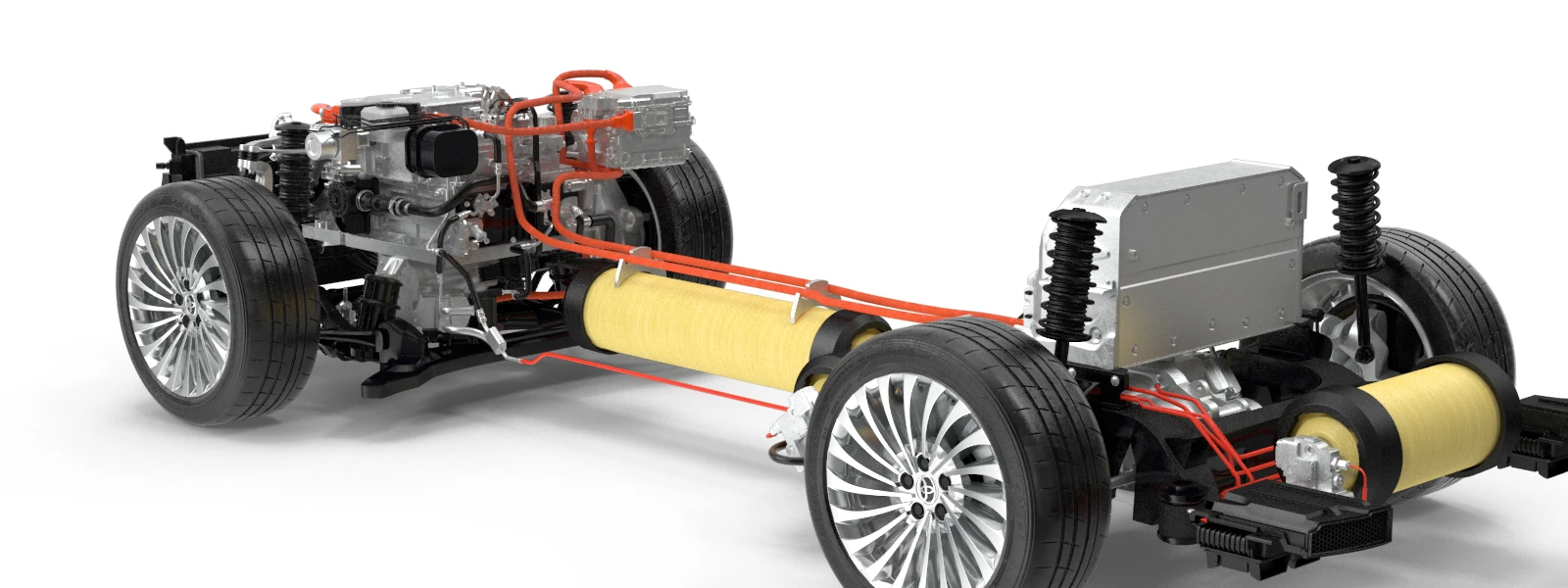

But what is a control arm? Although simplistic, it plays an essential role in the motion dynamics of every road-moving vehicle. A control arm is a hinged suspension link that connects the car's body and the suspension hub, which houses the car's wheels.

A flawed or defective control arm leads to several hazards. Therefore, the below article focuses on the ins and outs of the control arm(s) on vehicles to ensure safe and smooth rides.

Where Is a Control Arm Located?

Control arms are present in the front suspension system. They help the driver control the wheel motion of the vehicle through the steering wheel.

Now, the question arises do vehicles have control arms for rare wheels? Or do rear wheels play no part in the vehicle's motion?

To answer the above questions, peek under your car, and you will find that the rear wheels also use control arms. All vehicles have both front and back suspension systems. So naturally, control arms are present in both suspensions. However, the number of control arms differs. Most cars use one control arm, while others have two associated with each wheel.

Parts Of a Control Arm

Control arms consist of three major parts. Control arms come in different shapes like L-shaped, A-shaped, or wishbone, but they all have the same components. A ball joint, bushing, and chassis.

The suspension hub connects to the chassis with a bushing. Since the body and the control arms are metallic, their contact causes immense friction, leading to the component's wear.

Most vehicles have two bushings, one on the sway bar and the other where it connects to the wheel. Since both the sway bar and the wheel's interior are metallic, bushings are installed to prevent wear and improve drive quality and component durability.

Next comes the ball joint. The steering knuckle connects to the control arms via a ball joint. These joints allow comfortable movements in all directions. The ball joints help control the rotational motion of the wheels in different planes. Some are more limited than others. For instance, a single ball joint allows movement in two planes, including rotational movements. However, two ball joints are installed for more flexible motions as they provide motion in three planes. Worn-out joints provide less wheel control, ultimately inviting hazards along the ride.

What Does a Control Arm Do?

Now you have all the essential information to understand the working mechanism of the control arms. Let’s dive into the mechanics now.

The function of a control arm is nothing twisty. It connects the steering knuckle to the car body and wheel hub to stabilize the vehicle on the road. The control arm moves with the spring when the car hits a bump to maintain contact with the road and increases control. Stability is essential, especially on rougher terrains, as a shaky vehicle will ultimately lose its balance.

- A control arm links to the chassis by two bushings. The bushing reduces wear and permits the arm to move vertically up and down quickly. One end of the control arm fits with the steel spindle, which connects to the front wheel.

- The vehicles with wishbone suspension have spindles attached to both upper and lower arms with ball joints. Whereas in strut suspension, the spindle connects to only one control arm.

- Lastly, a steel coil is sandwiched between the control arm and the car frame, which supports the car's weight.

All the suspension system components rely on the control arm for synchronization. If the control arm is damaged, the driver will lose control, and more problems will follow.

Not all vehicles require an equal amount of control. Some heavy-duty vehicles require more wheel control as they travel on harsher terrains. Therefore, cars like trucks and SUVs have two control arms on each wheel. It means there is a total of four control arms present in the front suspension system. In contrast, everyday vehicles only have a single control arm for every wheel.

Types Of Control Arms

As explained earlier, all vehicles don't require the same strength and wheel control. Naturally, a drifting car needs more wheel control than an average sedan. Hence, the market offers two kinds of control arms; their details are below.

Lower Control Arms and Strut Suspension

The kind of control arm used depends on the suspension system. The most common suspension type is the Strut Suspension. Another mechanical term for strut suspension is the MacPherson Strut Suspension. It is the suspension found in most vehicles' front suspension systems.

There is only one control arm in this arrangement which controls the wheel synchronization and balance. The strut functions as a virtual upper control arm and supports the weight of the chassis.

Although this suspension arrangement is found chiefly in front wheels, some vehicles also use it in rear suspension systems. Modern-day cars use strut suspension systems for two prime reasons; affordability and lightness.

For more info about lower control arms, please refer to What is the lower control arm in a car, and What is a faulty lower control arm on a car

Upper Control Arms and Wishbone Suspension

Next is the wishbone suspension. In this suspension, there are two control arms. These are common for sports cars, high-class cars, and trucks. Wishbone suspensions demand more upfront but provide better wheel control and motion dynamics.

Vehicles having independent rear suspensions may have up to four control arms. These are called rear trailing arms or simply trailing arms. Independent suspension means both control arms are of different kinds. For instance, the upper control arms may be A-shaped, while the lower ones may be wishbone or any other, based on the manufacturer.

For more info about upper control arms, please refer to Upper control arm and its replacement

Adjustable Control Arms

Another common kind of control arm is found in lifting and racing vehicles. A crucial associated term with adjustable control arms is 'camber.' The vertical alignment of the wheels is called camber.

A camber has two possible alignments, negative and positive. The former means the wheels of the vehicle are tipped inwards. While the latter indicates the outward tipping of the wheels.

Adjustable control arms are needed in aftermarket suspension modifications. For instance, camber adjustment becomes necessary when a hydraulic kit is installed in a car or vehicle. Hence, using adjustable control arms becomes essential.

Although, adjustable control arms help ease the camber alignment process. But fixing a camber may be arduous if adjustable control arms are not present in the factory settings.

The Standard Materials Used in Control Arms

Cast Aluminum

Aluminum earns its reputation in the automotive industry due to its non-corrosive nature. Although it provides more rust resistance and lightness, aluminum is softer. Hence, too much force from the suspension system may bend, crack or break these control arms.

Cast Iron

Next comes the cast iron control arms. Cast-iron control arms stand on an upper rank on both aluminum and steel arms. These control arms are sturdier than aluminum arm controls and offer excellent resistance to rust.

Most modern vehicles, like SUV trucks, use cast iron control arms in their front suspension systems. They are present in other shapes, but wishbone-shaped ones are commonly used.

Stamped Steel

Steel is one of the oldest metals employed in most mechanical parts, and control arms are no exception. Steel control arms are cheap and provide good strength.

Their structure holds the spring coils in place and offers housing for sway bars. Steel control arms are highly vulnerable to rust despite their strength and affordability. Frequent exposure to wet environments causes them to rust rapidly compared to dry situations.

Changing ball joints and bushings of rusted arms is challenging as the component is likely to break. Fortunately, these are inexpensive to replace, and most mechanics prefer them for their easy cost.

Control Arm Replacement Tips

A control arm is prone to damage as it takes a stricter grind. Hence, you will require frequent replacements. If you are replacing the arms yourself, you must remember some tips.

- Always use the right tools for replacements.

- Replacing control arm parts is tricky as you may easily damage other components. It's best to do the complete arm replacement because it is relatively easy.

- Never forget to access the service manual. If you have an older vehicle, try searching for helpful material online. If you are still unsure what the problem is, consult a professional.

Older vehicles' control arms have detached ball joints that are serviceable independently. But newer ones have ball joints integrated within the control arm. Therefore, if the ball joints need replacement, you'll need to replace the entire arm. As for the cost of replacement, please refer to How much does control arm replacement cost

Conclusion

It is time to wrap up this fantastic informational post on control arm(s). A control arm is the essence of the suspension system. It helps keep the wheel intact with the road for increased equilibrium and control.

Since control arms are the most critical part of the car suspension system, they need constant inspection. Worn-out control arms cause unprecedented damages. Therefore, the driver must know the mattering aspects of control arms. The most important ones regarding their function and types are mentioned in this post.