What is a Diesel Pump?

You will always notice at gas stations that diesel fuel is always available. Its popularity is because it lets the diesel engine work, which is one of the best and most efficient engines in recent times

You will always notice at gas stations that diesel fuel is always available. Its popularity is because it lets the diesel engine work, one of the best and most efficient engines in recent times. You may also wonder why people use gasoline even when they know the best option is available. You can’t force someone to use something just because you use it; everyone has choices.

But the above queries lead to diesel engines and not diesel fuel. One thing to notice here is that diesel engines don’t use the ignition spark. Instead, they use physical compression to make the hot fuel burn, an ancient but effective way of making things work. For more components of a diesel engine, please refer to Which type of pump is used in diesel engine

Let’s look at what makes the diesel engine different from a simple engine and how you can use it in the best possible way.

Difference between Diesel Engines and other Engines

Increasing the heat content of something requires you to put that on fire. But you can’t apply the same thing to gases or gaseous fuels used in engines because this may overheat them, ultimately leading to an explosion. You must use controlled Temperature and Pressure conditions to operate a Diesel engine or a simple heat engine. The efficiency can undoubtedly be increased by increasing the temperature of heat addition or by decreasing the temperature of heat rejection. But you can’t increase the former so that it crosses the limit. It also affects the turbine blades next to the boiler, ultimately generating work. So, make sure that you take these factors into account before supplying heat content to an engine.

A diesel engine simply compresses the air (that contains Oxygen) to 1/20 of its original volume. The diesel fuel is then injected and then pumped inside it. All this is done using pistons, and the upward and downward motion of the piston is what we call a stroke. When the fuel enters through the inlet valve, the piston starts moving downward from the Top position, also known as Top Dead Center. As soon as it reaches the bottom, enough pressure is reduced because of the increase in volume, and the fuel enters the tank.

In the next part, the piston starts to move upward, giving rise to pressure that becomes so high that you can ignite it (because the increase in pressure increases the temperature also). And the best part is that no heat enters or leaves the system during this phase, it’s just the system's pressure that helps it in the burning stage, or you can say, helps in the ignition of the fuel.

If you talk about other engines, such as petrol engines, they work on the same phenomenon, but you have to introduce an external ignition source, which is usually a spark. So, the diesel engine is quite different from other kinds of engines in many ways.

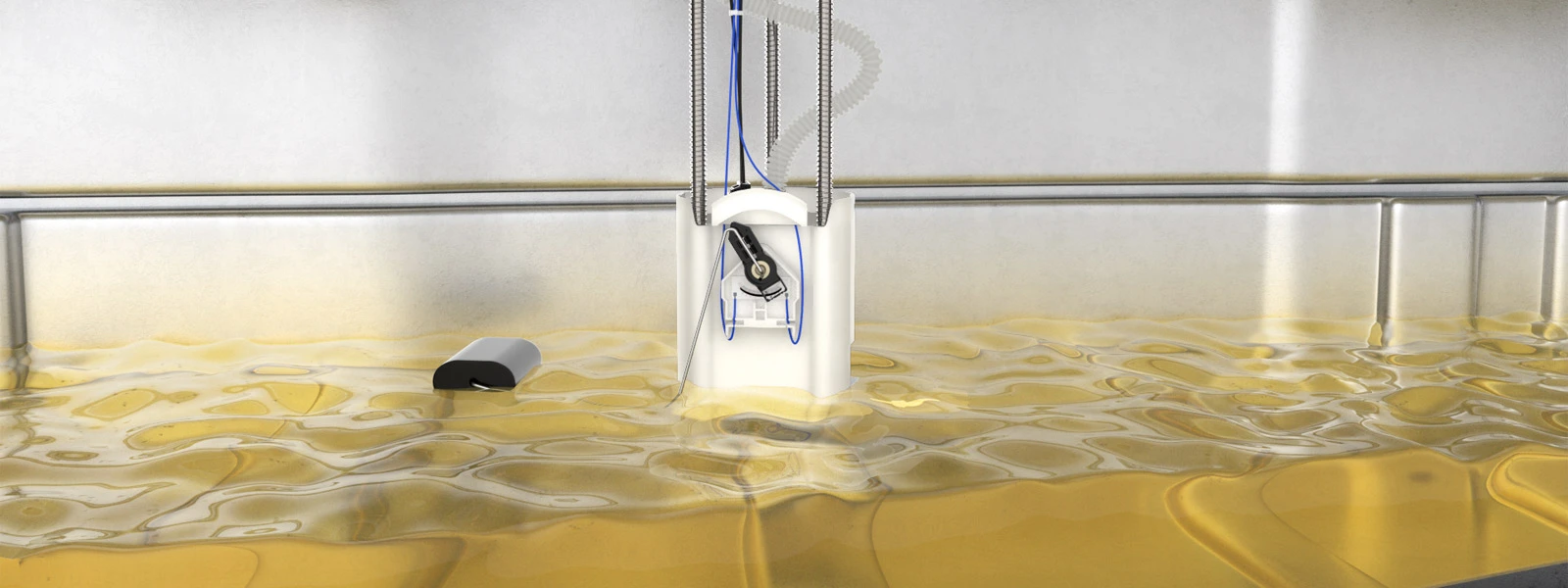

How does a Diesel Pump work?

Diesel Pumps are similar in performance to petrol engines, and both are IC devices that use internal combustion systems for powering the vehicles. Both contain a mixture of fuel and air, which, when ignited, tends to deliver a force that helps the vehicle move. The difference between a diesel pump or engine and a petrol engine is mentioned above, and the former doesn’t use an external source to be ignited while the latter does.

A petrol engine's fuel pump is crucial and plays a vital role in its working. But it isn’t as important as the diesel pump for a diesel engine. Since diesel engine doesn’t contain spark plugs, unlike other engines, it is supposed to work efficiently as long as the temperature and pressure given to the fuel are sufficiently high. Once the pressure is reduced, you may also have to ignite the mixture in the diesel engine. For the same reason, it is more critical to a diesel engine than a fuel pump for a petrol engine. This diesel pump supplies the compressed air used to provide the heat.

The performance of a diesel pump also depends on the pump you are using for this purpose. For example, using an inline injection pump indicates that each of the cylinders will have a plunger and a pump attached to it. When you put the fuel in that pump, one of the ends will let it enter the combustion chamber while the other contains the plunger. The plunger’s back & forth movement creates an opening through which the fuel enters the part where combustion will take place.

However, if you need a more efficient and modern pump, you can also use a Distributor Injection Pump. You will just need to specify the number of valves to maintain the pressure and quantity of fuel that will enter the combustion chamber.

At what temperature and pressure do a Diesel Pump work well?

A few kinds of pumps are used in a diesel engine, but the standout one is the “Fuel Injection Pump.” The injection system comprises a pump, nozzle or injector, and a fuel line. When the pump compresses the air inside the engine, its pressure rises to 400-600 psi. And if you compare it with atmospheric pressure, which is 15 psi under normal circumstances, you can notice how much the compression is. And since gases are compressible, the temperature increases as soon as the pressure increases and ultimately becomes almost 600℃.

Both gasoline and Diesel engines have almost the same arrangement and cycles. The only difference is the way the ignition occurs. If we compare both of them, diesel engines are better in terms of efficiency as the power generation per kg of fuel is more in them. Also, there is no such fire hazard in these engines, which is undoubtedly present in gasoline and petrol engines.

Are there any disadvantages of Diesel Engines?

Diesel engines aren’t always advantageous. Instead, they may cost you some amount if they stop working the way they are supposed to do. That is because of the high pressure, which increases the temperature. So, if the specified limit is crossed, you may face challenges as an owner, which is not what you want. One of the challenges is the difficulty in starting the engine as well.

How to know if the diesel pump is working well?

To get an idea of whether the diesel pump is working well, you must measure the quantity of fuel being used in a specified time. You can use flow meters also for this purpose. This will also let you know how you can enhance power generation. The same flow meters will help you determine the fuel flow rate through the pipelines.

After that, you can calculate the pumping cost for one liter, mega liter, or something like that. The efficiency of a diesel pump varies depending on the type of fuel being used in it, along with the air. You must also see whether the air entering the pump contains contaminants. If it does, use air filters to remove them, or those contaminants will damage the fuel pump. Also, see whether the fuel you are using is volatile or not. Sometimes, more volatile fuels leave their vapors inside the engine, which also makes the engine suffer because ignition occurs before time, causing the system's performance to go down. So, you must consider all these factors, which is the only way to determine whether the diesel pump is working well.

What are the Types of Diesel Pumps?

A diesel pump doesn’t exist. Instead, we call a Fuel Injection Pump as Diesel Pump. Such a pump contains an injection system for making the entire engine work properly. It also distributes the fuel to injectors and has many other jobs. It is mainly of three types:

An inline Pump has a fuel barrel and plunger to pump the fuel and is used when the plunger provides enough back-and-forth motion.

The distributor Pump contains a distributor to provide the fuel to injectors and uses the motion of plungers to do so.

A continuous Pump just maintains the pressure instead of supplying the fuel.

So, all these types of diesel pumps are used under different circumstances based on the quantity of fuel needed or the pressure required.

Conclusion

A diesel pump makes a diesel engine work, and it plays a vital role in increasing or decreasing the engine's efficiency. You just need to adjust the temperature and pressure of the fuel mixture entering the engine. Don’t keep it too high as it will damage the blades of the turbine, while it shouldn’t be too low. So, consider all the factors and then see whether the diesel pump is working well.