What are Oil Cooler Lines: Things You Need to Know

The oil cooler lines are a critical component of the engine's cooling system. They play a vital role in regulating the temperature of the engine oil, which is essential for the proper operation and longevity of the engine.

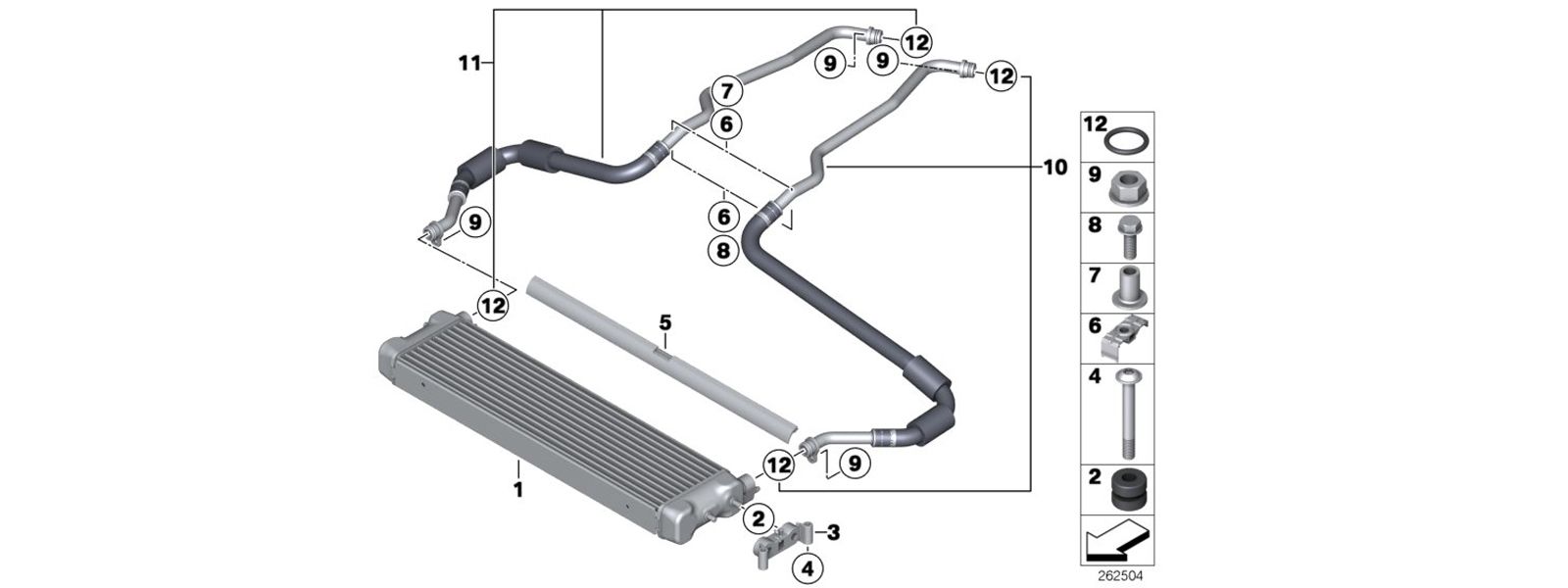

The engine's oil cooling system comprises interconnected components known as oil cooler lines, also called oil cooler hoses. These elements facilitate the movement of engine oil from the pump, through the oil cooler, and back to the engine. The oil cooler functions as a heat exchanger, reducing the temperature of the oil before it recirculates into the engine, helping to maintain optimal operating conditions.

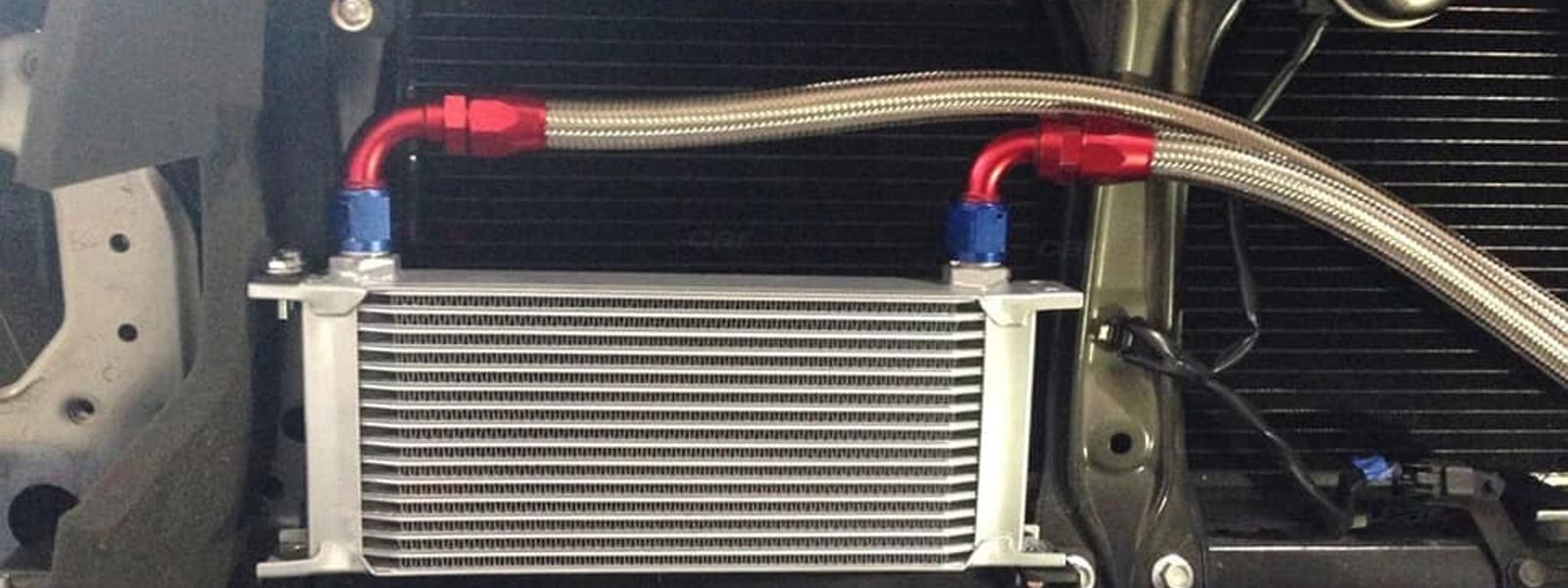

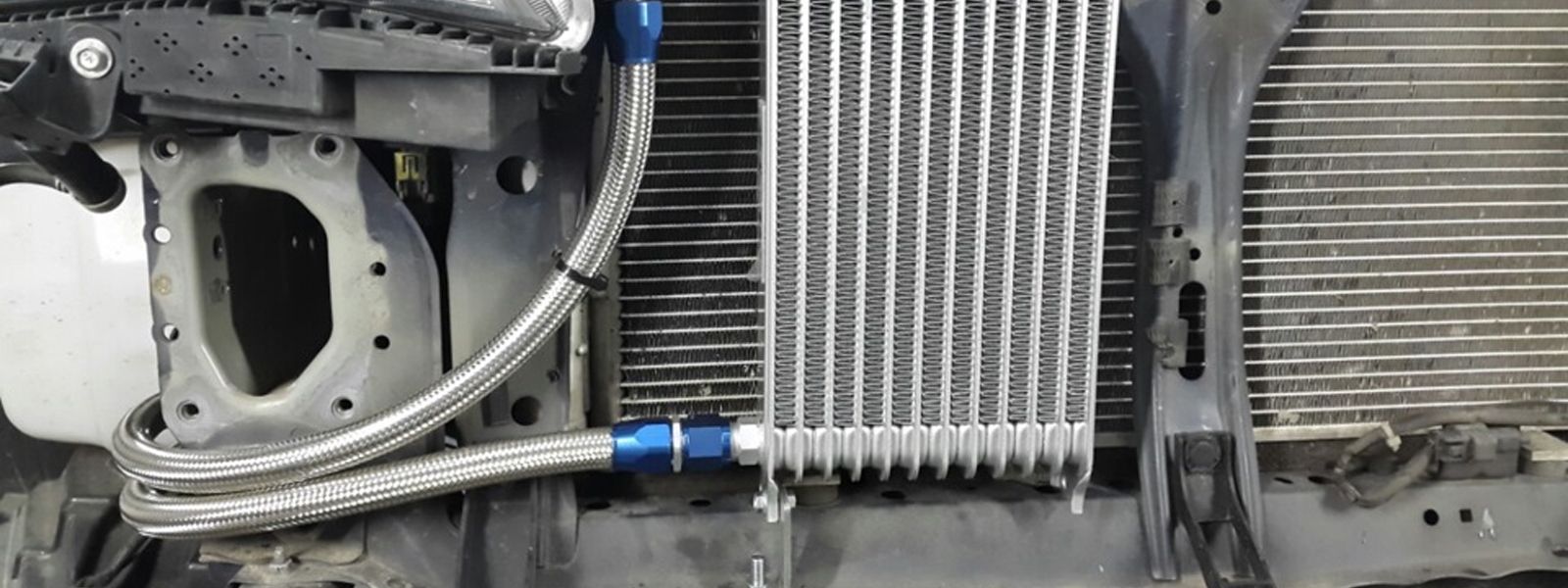

To withstand the elevated temperatures and pressures inherent to the oil system, the cooler lines are commonly constructed using robust materials such as rubber hoses, steel-braided hoses, or rigid metal tubing. The connections at each end of the lines utilize threaded fittings or specialized connectors to create a secure, leak-proof seal.

Functions of oil cooler lines

Oil cooling lines are an integral component of a vehicle's engine cooling system. Their primary function is to circulate the engine oil from the engine block to the oil cooler and back, helping to regulate the temperature of the engine oil and maintain it within the optimal operating range.

The engine oil serves crucial functions within the engine. It lubricates the moving components, reducing friction and wear, while also helping to dissipate the heat generated during engine operation. However, as the oil circulates through the engine, it is exposed to high temperatures, which can deteriorate the oil's lubricating properties over time, potentially resulting in increased engine wear.

The oil cooler lines function as the lifeblood of the engine's cooling system. They carry the hot oil from the engine to the oil cooler, where it is effectively cooled before being pumped back into the engine. By preserving the oil at the optimal temperature, the cooler lines play a vital role in ensuring the engine operates smoothly, efficiently, and with minimal risk of damage due to overheating.

Materials used for oil cooler lines

Oil cooler lines come in various materials, each with advantages and tradeoffs. Steel lines are highly durable and resistant, making them suitable for high-performance applications, but can be more rigid and prone to kinking. Aluminum lines are lighter and more flexible, simplifying routing and being less expensive, but may be more susceptible to damage. Rubber lines offer a flexible and robust alternative, but may have a shorter service life. The choice depends on the specific vehicle, application, and manufacturer recommendations.

The choice of oil cooler line material depends on the specific vehicle, its cooling system requirements, and operating conditions. Some vehicles use a combination of materials to leverage their respective strengths. Proper maintenance and regular inspections of the oil cooler lines are essential to prevent issues that could lead to engine damage or reduced cooling efficiency.

Oil cooler line replacement

Maintaining the oil cooler lines is a crucial upkeep task to guarantee the proper operation of the engine's cooling system. This preventative measure aids in avoiding potential problems and preserving optimal performance, ultimately prolonging the engine's lifespan and circumventing expensive repairs.

The process typically involves draining the engine oil, disconnecting the old oil cooler lines, and then installing the new replacement lines. When disconnecting the old lines, it's important to take note of their routing and placement for reference when installing the new ones. The new lines should be positioned following the original routing and the fittings tightened to create a secure, leak-free seal.

After the new lines are installed, the engine oil is refilled, and the engine is started to inspect for any leaks at the connections. Finally, the cooling system is tested to ensure the oil cooler is functioning properly and maintaining the engine's optimal operating temperature. Performing this maintenance task with care and attention to detail is crucial for the long-term health and performance of the engine.

How often to change the oil cooler line

As a general guideline, it's recommended to inspect the oil cooler line during regular engine oil changes or tune-ups, which are typically performed every 5,000 to 10,000 miles (8,000 to 16,000 km) or once a year, whichever comes first.

During the inspection process, the oil cooler line should be checked for the following:

- Signs of Wear and Tear: Over time, the oil cooler line can become brittle, cracked, or damaged due to exposure to heat, pressure, vibration, and chemical exposure. Any visible signs of deterioration warrant a replacement.

- Leaks or Seepage: Examine the fittings and connections of the oil cooler line for any signs of oil leaks or seepage, which could indicate a problem with the line.

- Kinks or Restrictions: Ensure the oil cooler line is properly routed without any kinks or restrictions that could impede oil flow.

As a general prudent practice, replacing the oil cooler line every 5-7 years or 50,000-100,000 miles (80,000-160,000 km), whichever comes first, is recommended, even if the component appears to be in satisfactory condition during the inspection. Proactively replacing the oil cooler line helps maintain the oil cooler's optimal performance, preventing potential issues and ensuring the engine's cooling system operates efficiently, thereby extending the engine's lifespan and avoiding costly repairs.

The oil cooler line replacement interval varies based on the vehicle's specifics and manufacturer recommendations. Refer to the service manual or consult a technician for the best replacement guidance. Diligent maintenance and timely oil cooler line replacement can significantly extend the cooling system's lifespan and avoid costly engine repairs.

A-Premium oil cooler line products are reliable and offer a variety of material options to choose from. You can find the right fit for your vehicle by using the vehicle selector on the A-Premium website - just input your vehicle's year, make, model, trim, and engine. A-Premium also provides excellent service, including fast shipping, easy returns, and a 3-year warranty policy, ensuring a hassle-free customer experience.